PREVENTATIVE MAINTENANCE

Preventative maintenance

Example: Food industry

EXAMPLE:

THE FOOD INDUSTRY

In the food industry, particularly high product quality requirements are usual. For example in the area of chocolate manufacturing:

Tempered chocolate is poured into moulds, after which the moulds are reused. Frequently the moulds are subject to wear over time, and must be replaced. In the past, such wear could really only be identified on the basis of defective products. Accordingly, these goods had to be disposed of (or sold as so-called factory seconds), since for premium products faulty shapes do not go into the regular trade.

With our inspection system, the moulds are inspected after each use, and defects that were previously undetectable can now be identified in good time, before they cause production defects. This inspection system generates images of the material structure of the moulds, and our image detection software analyses these images and reports defects completely automatically.

Thus, the mould can be replaced in good time and defective goods are almost completed avoided.

- Real time inspection of casting moulds

- Automatic detection of material defects

- Timely replacement of production equipment

- Reduction of rejects and production failures

EXAMPLE: INDUSTRY

Example: Industry

The inspection of safety-related components represents an example from the industrial sector. The specific application is the in-depth quality inspection of the material used.

It is essential that the wheels (rims, tyres, bearings) used in mass transport vehicles, such as buses or aeroplanes, are free of defects. Various quality inspections are performed to ensure this. One of these inspections pertains to the material structures themselves.

Irregular structures of the material (plastic or metal) are potential fracture points and constitute a significant risk. With our X-ray system we can completely penetrate the material and generate images that make specific material faults visible. The corresponding image recognition software is able to analyse the generated images and identify material that is not free of faults. System safety is increased, and costly downstream delays and downtimes are also avoided.

- Inspection of products immediately prior to use

- Automatic detection of material defects

- Timely replacement of products

- Increased safety and reduced downtimes

Request a personal consultation appointment now

Simply use our Contact Form to request a consultation appointment. Provide some information about your subject of interest, and we will get back to you as quickly as possible.

We look forward to your enquiry!

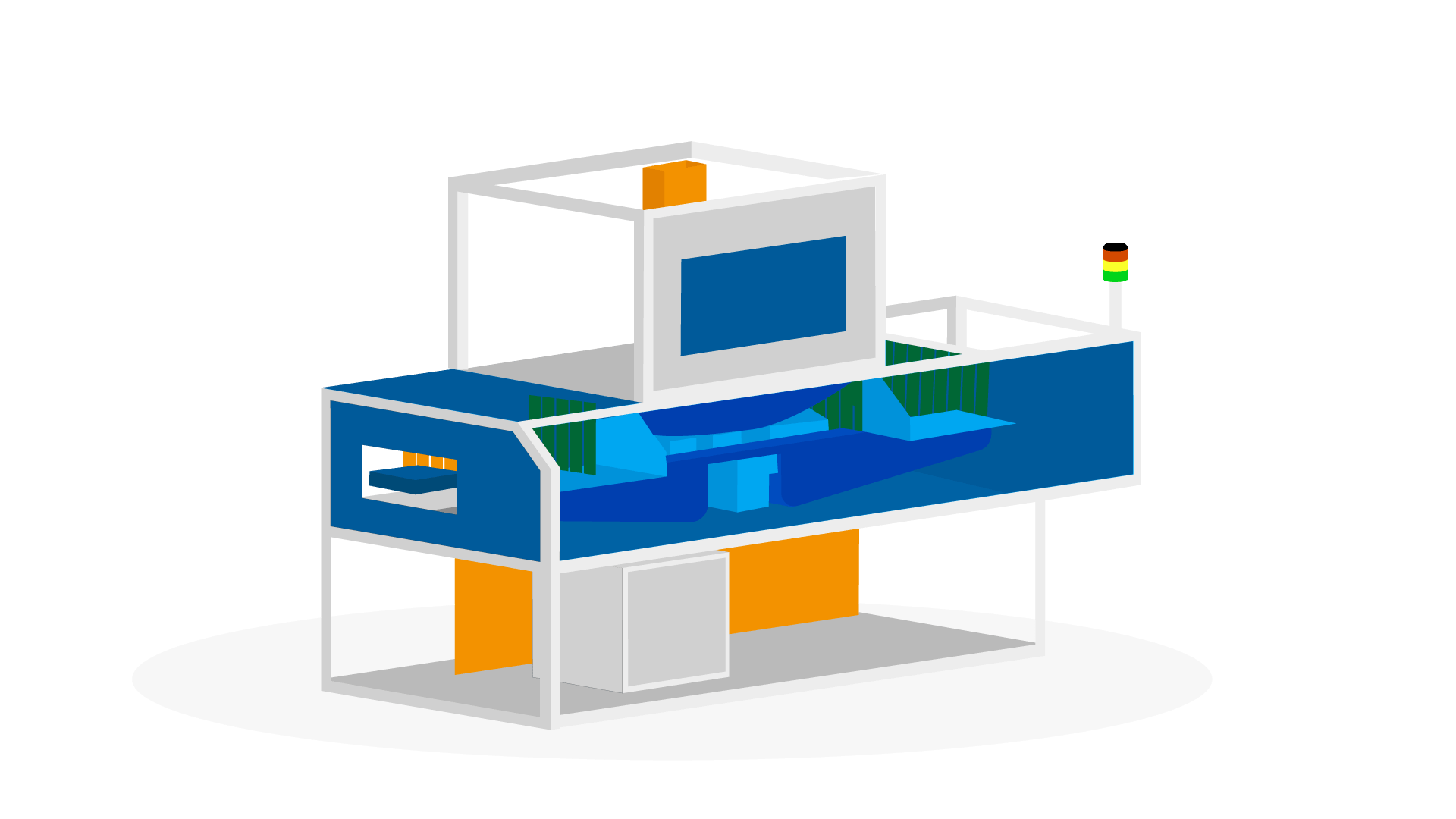

The X-ray tube and X-ray generator combine together to form the team which creates the radiation.

At IMS the X-ray generator and the X-ray tube are carefully matched to each other.

For example, if you are looking for an X-ray generator to replace an existing device, please contact us to discuss your requirements.

This is where all the information comes together and is processed, and corrections and countermeasures (where necessary) are organised.

It is always a challenge to transfer the skills of reliably recognising deviations, defects, or damage into an inspection system. For this, IMS uses its own developments which are tailored to requirements in collaboration with universities, institutes of higher education, and our own customers. As the provider and developer of all core components, IMS offers you systems from a single provider, completely tailored to your needs, and always with a sustained focus on:

- Reliability

- Availability

- Upgradability

- Compatibility with your software solutions and protocols

Many applications are possible; here are some examples:

- Food products: foreign objects in raw or packaged food products

- Consumables: determining the quality of fine-cut tobacco

- Production resources: defect detection in chocolate confectionery moulds

- Industrial products: completeness inspections for assortment boxes or PCBs

- Incoming goods testing: random sampling of weld seams or iron castings

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Safety is the top priority when working with X-ray radiation. IMS is committed to all occupational health and safety aspects in every area, whether manufacturing or later for operational X-ray systems. Safe shielding and shut-down measures protect operators and maintenance personnel from the generated X-ray radiation.

An X-ray tube generates the radiation necessary to illuminate the object to be inspected.

The intensity of the radiation required varies, depending on density and material thickness. IMS provides X-ray systems that fulfil the respective requirements. Contact us. We would be pleased to work together with you to determine the X-ray system that is right for you.

This is where the X-ray image is created; resolution and scan speed can be selected appropriate for the respective requirement. We will be happy to help you with the evaluation. Contact us. It is our pleasure to advise you.

A conveyor is the most widely used option for implementation of inline or online testing and inspection of products and tools. Conveyors can also be flexibly adapted to meet virtually all requirements, for instance:

- They can be disinfected

- Width and length

- Load capacity

- Resistance to chemicals

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Various solutions are possible.

- A standalone solution without connection

- Or else with an Ethernet connection

Inline, atline, and online solutions, in particular, make it possible to record and process important quality information very quickly. Corrective work is implemented earlier, and scrap is avoided.

The X-ray inspection system can also be monitored via remote diagnosis. Corrections can be made and software can be updated without the physical presence of a service technician.