Insightful

Quality Control

Explore New Possibilities: IMS X-ray inspection systems provide a glimpse into the unseen. Detect defects, foreign objects, and more early on. Enhance customer satisfaction and reduce your claim costs.

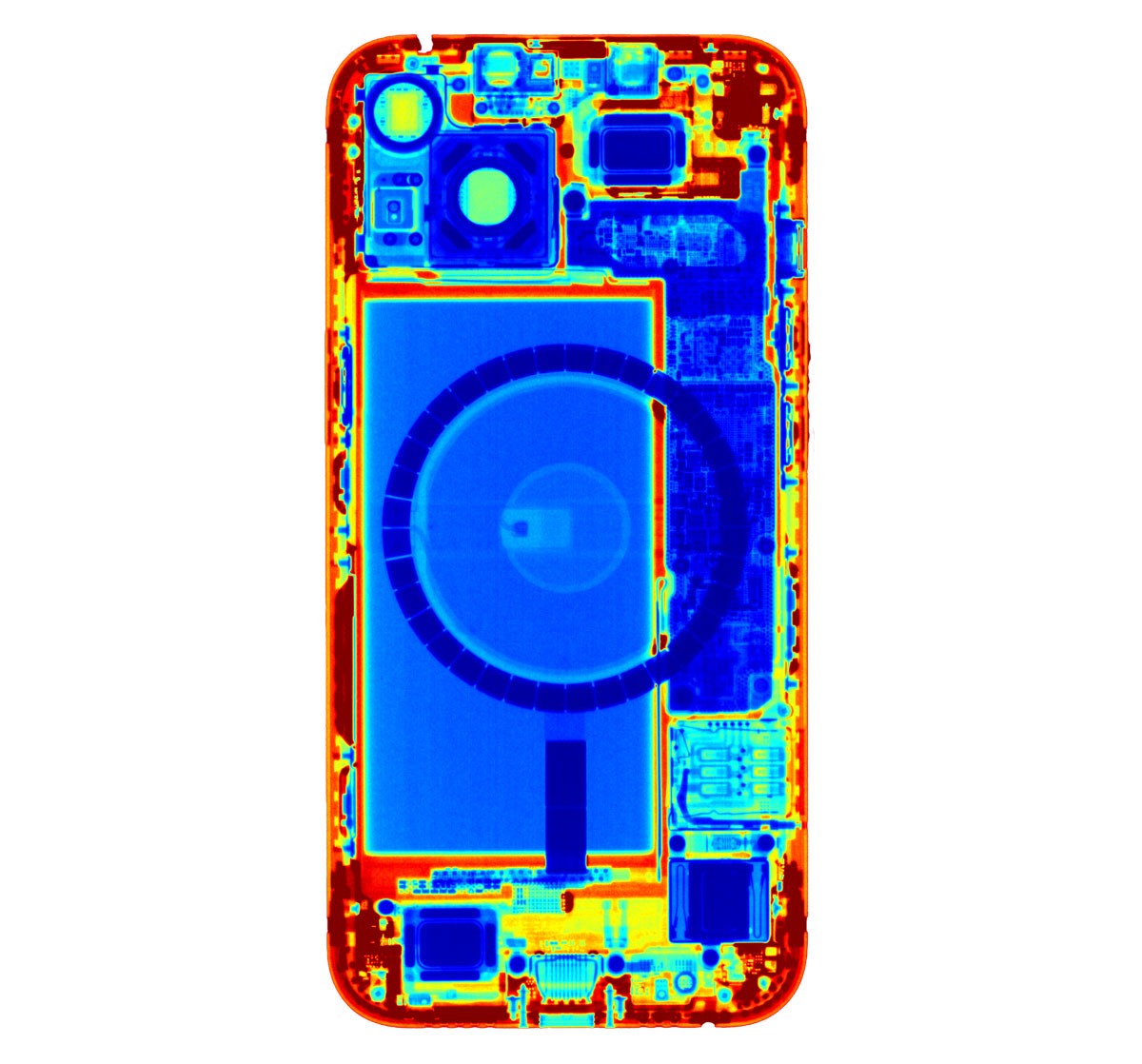

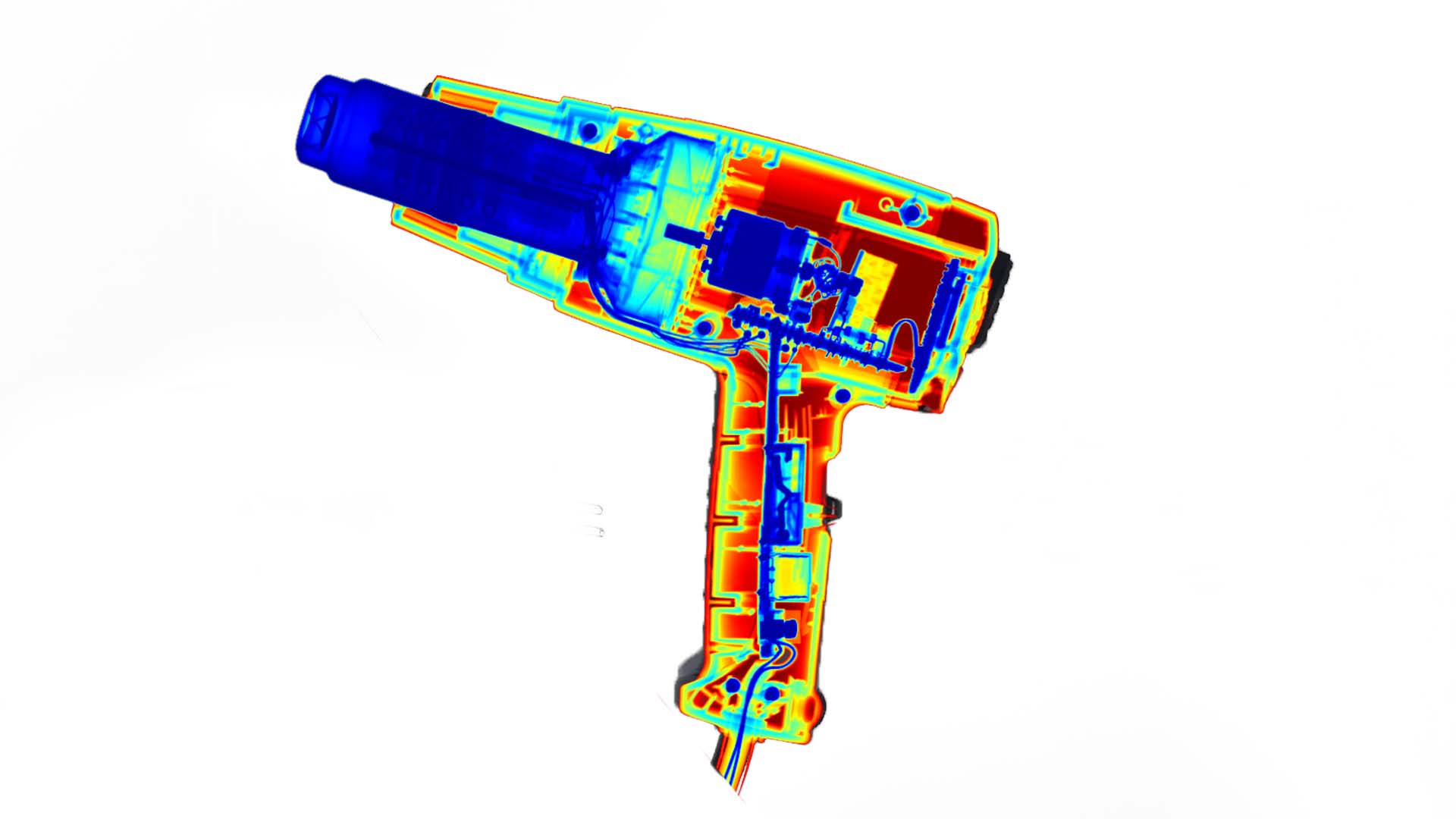

In the tiniest spaces:

We peer into smartphones.

Why is this crucial? We uncover defects in technical components of every scale, seamlessly integrated into your production environment. Fully automated and in real-time. This elevates your product quality and significantly reduces the rejection rate. What can we do for you?

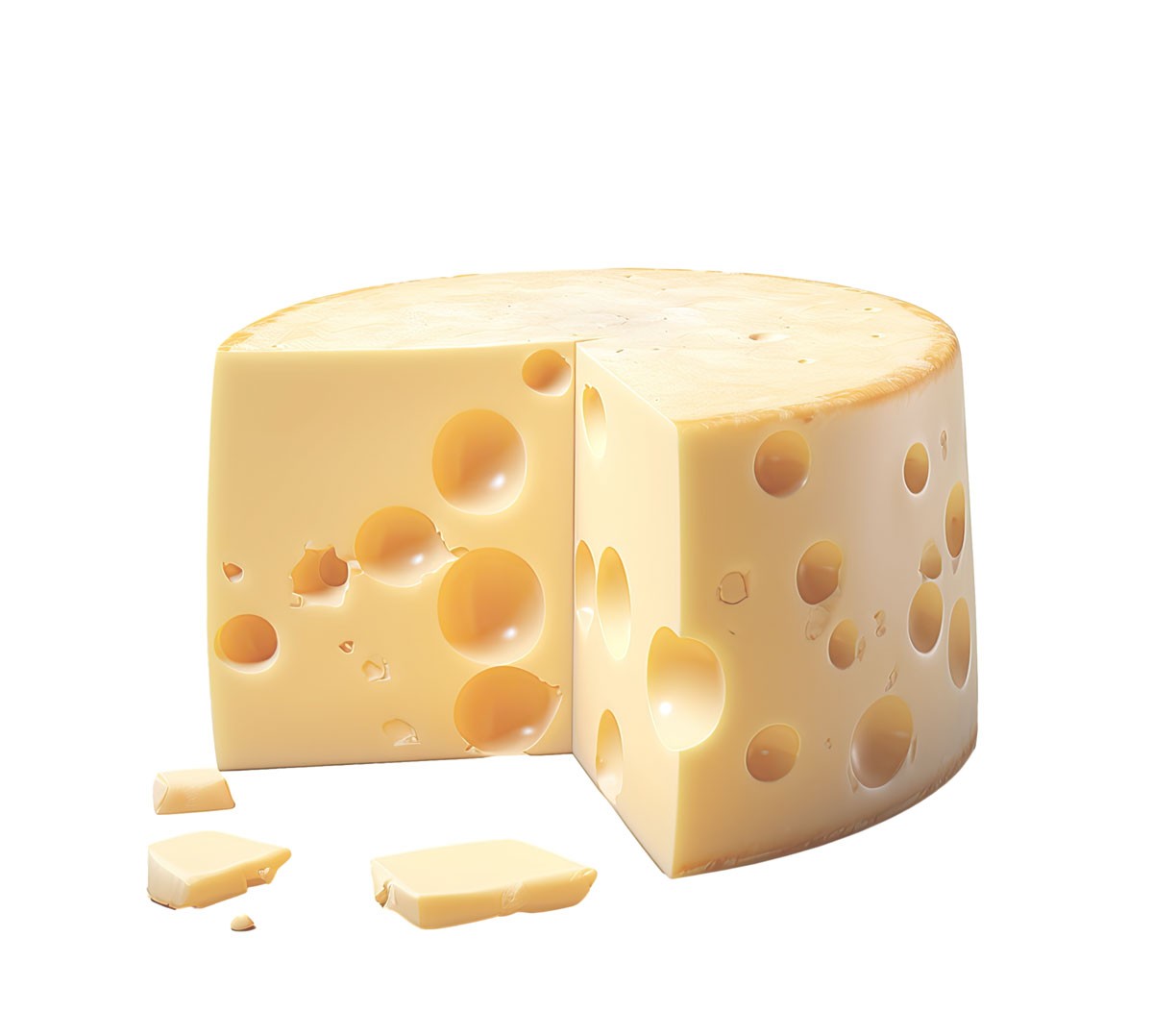

Without breaking the surface:

We locate the holes in cheese.

Why this matters? The composition of organic structures is crucial for many applications, such as precise portioning in the packaging process and numerous other uses. Non-contact inspection of organic structures poses no challenge for us. We deliver fully automated analyses and real-time results for your production line. Perfect for non-contact inspection of inhomogeneous products. What can we do for you?

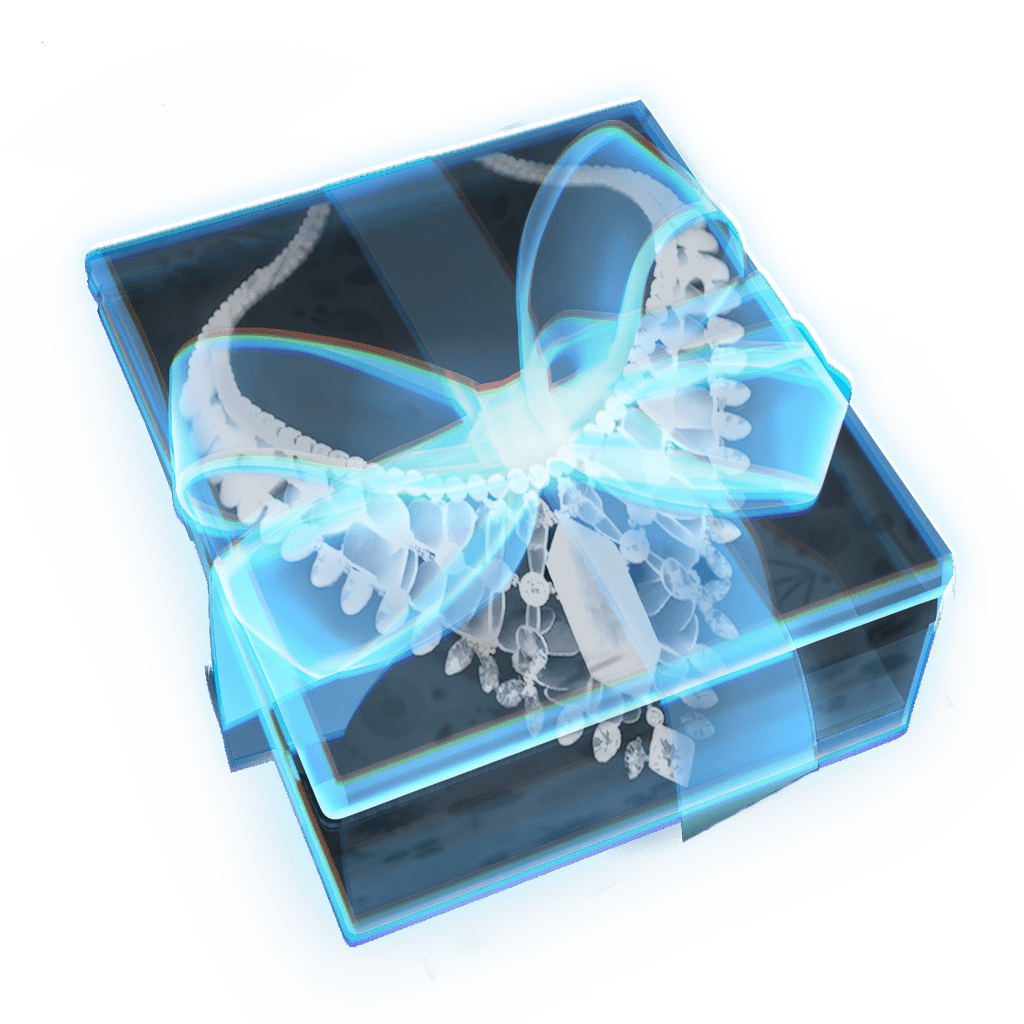

Unveiling the Interior:

We reveal the contents.

Why it’s crucial: Swift and non-damaging inspection of packaged products elevates quality and efficiency. Opaque containers pose no challenge for us when it comes to looking inside. Detecting foreign objects or verifying completeness can be achieved in this manner, from the outside, contactless, and in real-time. How may we assist you?

Our X-ray solutions offer numerous benefits for you and your customers.

- Ensuring High Quality

- Sustainability through gentle inspection

- No disruptions in workflow

- Early risk mitigation

- Automatic detection of material defects

- Reducing scrap and production incidents

Request a feasibility study now

How can we assist you?

+49 (0)2056 / 975-0

or call us.

Request a personal consultation appointment now

Simply use our Contact Form to request a consultation appointment. Provide some information about your subject of interest, and we will get back to you as quickly as possible.

We look forward to your enquiry!

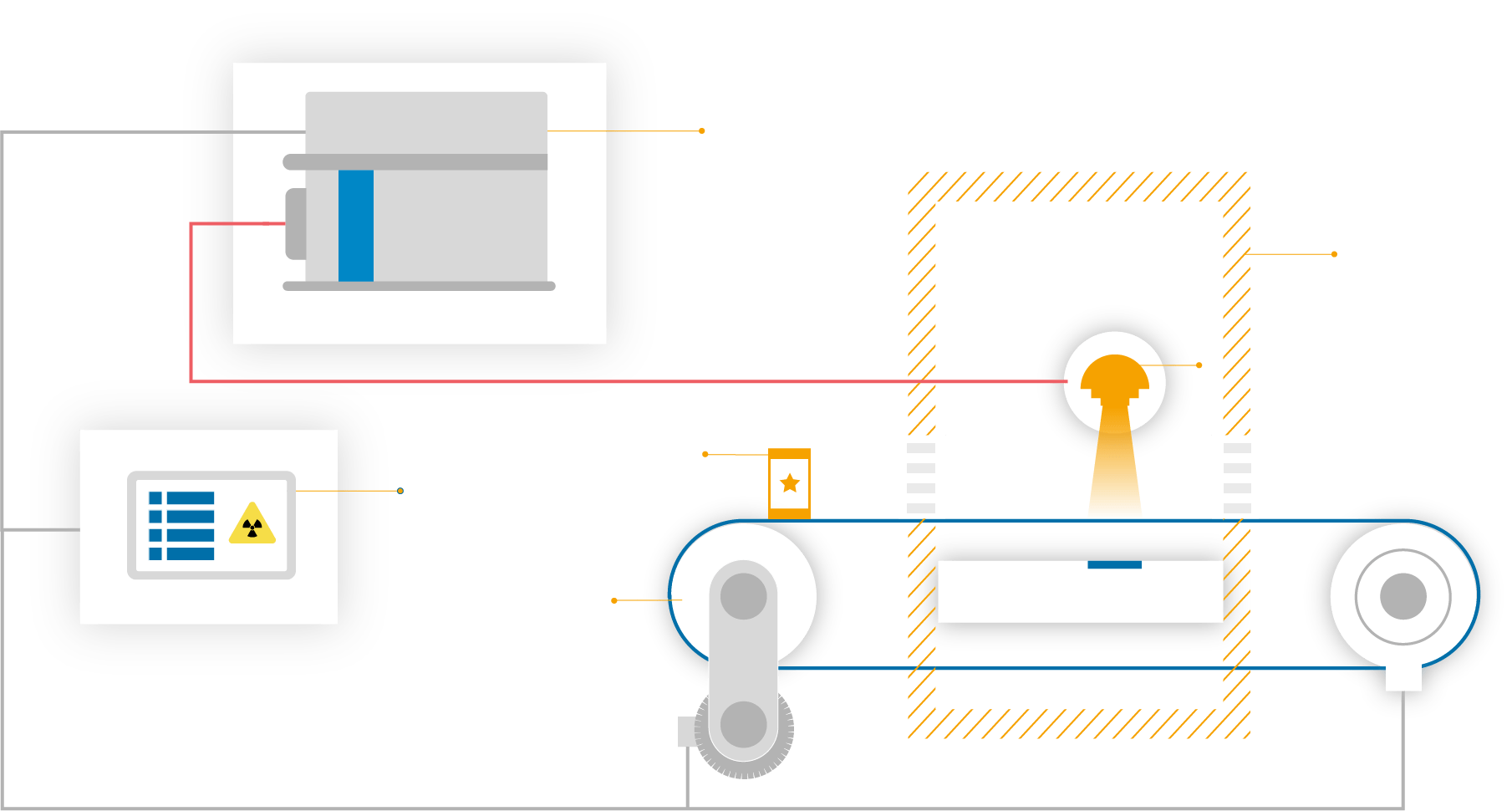

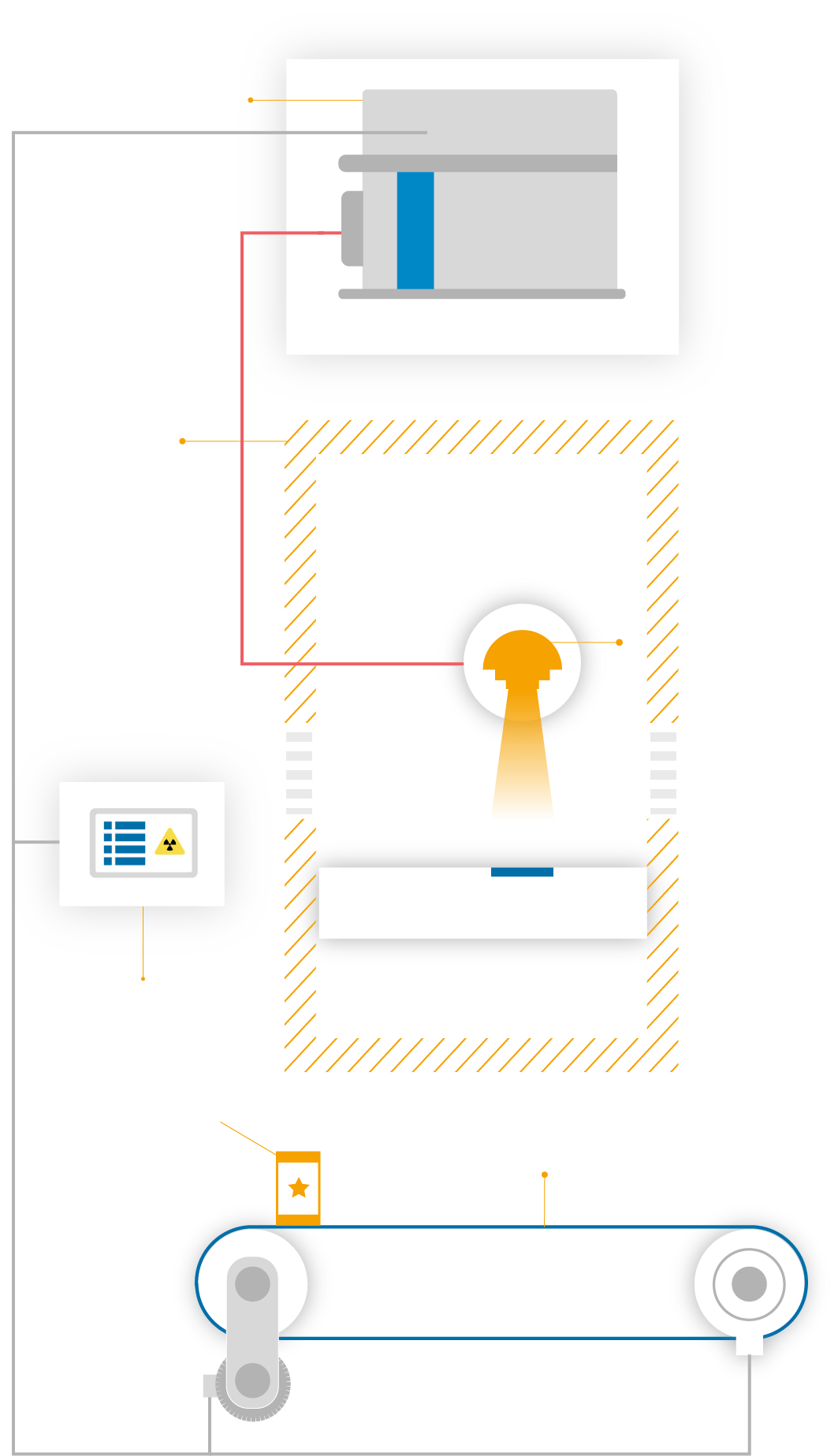

A schematic diagram of an X-ray inspection system

The X-ray tube and X-ray generator combine together to form the team which creates the radiation. At IMS the X-ray generator and the X-ray tube are carefully matched to each other.

For example, if you are looking for an X-ray generator to replace an existing device, please contact us to discuss your requirements.

This is where all the information comes together and is processed, and corrections and countermeasures (where necessary) are organised.

It is always a challenge to transfer the skills of reliably recognising deviations, defects, or damage into an inspection system. For this, IMS uses its own developments which are tailored to requirements in collaboration with universities, institutes of higher education, and our own customers. As the provider and developer of all core components, IMS offers you systems from a single provider, completely tailored to your needs, and always with a sustained focus on:

- Reliability

- Availability

- Upgradability

- Compatibility with your software solutions and protocols

Many applications are possible; here are some examples:

- Food products: foreign objects in raw or packaged food products

- Consumables: determining the quality of fine-cut tobacco

- Production resources: defect detection in chocolate confectionery moulds

- Industrial products: completeness inspections for assortment boxes or PCBs

- Incoming goods testing: random sampling of weld seams or iron castings

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Safety is the top priority when working with X-ray radiation. IMS is committed to all occupational health and safety aspects in every area, whether manufacturing or later for operational X-ray systems. Safe shielding and shut-down measures protect operators and maintenance personnel from the generated X-ray radiation.

An X-ray tube generates the radiation necessary to illuminate the object to be inspected. The intensity of the radiation required varies, depending on density and material thickness. IMS provides X-ray systems that fulfil the respective requirements. Contact us. We would be pleased to work together with you to determine the X-ray system that is right for you.

This is where the X-ray image is created; resolution and scan speed can be selected appropriate for the respective requirement. We will be happy to help you with the evaluation. Contact us. It is our pleasure to advise you.

A conveyor is the most widely used option for implementation of inline or online testing and inspection of products and tools. Conveyors can also be flexibly adapted to meet virtually all requirements, for instance:

- They can be disinfected

- Width and length

- Load capacity

- Resistance to chemicals

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Various solutions are possible.

- A standalone solution without connection

- Or else with an Ethernet connection

Inline, atline, and online solutions, in particular, make it possible to record and process important quality information very quickly. Corrective work is implemented earlier, and scrap is avoided.

The X-ray inspection system can also be monitored via remote diagnosis. Corrections can be made and software can be updated without the physical presence of a service technician.

The X-ray tube and X-ray generator combine together to form the team which creates the radiation. At IMS the X-ray generator and the X-ray tube are carefully matched to each other.

For example, if you are looking for an X-ray generator to replace an existing device, please contact us to discuss your requirements.

This is where all the information comes together and is processed, and corrections and countermeasures (where necessary) are organised.

It is always a challenge to transfer the skills of reliably recognising deviations, defects, or damage into an inspection system. For this, IMS uses its own developments which are tailored to requirements in collaboration with universities, institutes of higher education, and our own customers. As the provider and developer of all core components, IMS offers you systems from a single provider, completely tailored to your needs, and always with a sustained focus on:

- Reliability

- Availability

- Upgradability

- Compatibility with your software solutions and protocols

Many applications are possible; here are some examples:

- Food products: foreign objects in raw or packaged food products

- Consumables: determining the quality of fine-cut tobacco

- Production resources: defect detection in chocolate confectionery moulds

- Industrial products: completeness inspections for assortment boxes or PCBs

- Incoming goods testing: random sampling of weld seams or iron castings

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Safety is the top priority when working with X-ray radiation. IMS is committed to all occupational health and safety aspects in every area, whether manufacturing or later for operational X-ray systems. Safe shielding and shut-down measures protect operators and maintenance personnel from the generated X-ray radiation.

An X-ray tube generates the radiation necessary to illuminate the object to be inspected. The intensity of the radiation required varies, depending on density and material thickness. IMS provides X-ray systems that fulfil the respective requirements. Contact us. We would be pleased to work together with you to determine the X-ray system that is right for you.

This is where the X-ray image is created; resolution and scan speed can be selected appropriate for the respective requirement. We will be happy to help you with the evaluation. Contact us. It is our pleasure to advise you.

A conveyor is the most widely used option for implementation of inline or online testing and inspection of products and tools. Conveyors can also be flexibly adapted to meet virtually all requirements, for instance:

- They can be disinfected

- Width and length

- Load capacity

- Resistance to chemicals

And there are many others. Please contact us. It would be a pleasure to discuss your requirements.

Various solutions are possible.

- A standalone solution without connection

- Or else with an Ethernet connection

Inline, atline, and online solutions, in particular, make it possible to record and process important quality information very quickly. Corrective work is implemented earlier, and scrap is avoided.

The X-ray inspection system can also be monitored via remote diagnosis. Corrections can be made and software can be updated without the physical presence of a service technician.

Innovative inspection systems

for a wide range of applications

Join us in discovering new possibilities for optimising the quality of your products and processes. We specialise in non-contact inspection of a wide variety of organic and inorganic materials.

IMS X-ray systems

X-ray systems require optimisation for every application. The multiple requirements in special technical niche areas demand flexibility. For some applications high stability and long-term reliability play the major roles, in other applications price-optimised solutions are desired. The requirements of our customers are at the forefront of our business activities.

Only companies who can consistently deliver faultless products can compete long-term in the global market. This capability is ensured with safe, high-performance, robust inspection systems that can be used in a production process while it runs, and that enable non-destructive material testing.

In recent years IMS Röntgensysteme GmbH has grown by meeting these quality requirements consistently. Since 2000 we have been developing and manufacturing X-ray generators, control units and complete systems to meet the needs of our clients.

Our products include X-ray systems for measuring the thickness of cold-rolled and hot-rolled strip in steel production, and for microstructure examination of fully assembled PCBs, or of the smallest castings. Application areas include medical technology (computer tomography) or the food industry (foreign object detection).

More than 5,000 IMS systems are in operation around the world – each designed for a very particular task. With our own development department and a clear production structure we can respond quickly and flexibly to special customer requirements.

As an IMS customer, you benefit from this through continuous product quality, short downtimes of your production lines, and the resulting sustainable cost reductions. Use our experience and know-how.

Special solutions: It all starts with the customer requirement

Our expertise is identification of the specific requirements together with our customers and, from these requirements, development of practical solutions with a high utility value. Many of the IMS systems established today were originally developed and designed individually on the basis of customer enquiry. But our portfolio also includes customer-specific special solutions that have been used only once, for a special application.

At IMS Röntgensysteme, we see ourselves as a self-learning organisation whose enterprise concept is aligned to a permanent high level of knowledge expertise.

Maybe the portfolio presented here seems initially not to include an approach to your specific inspection task? Or perhaps the inspection task is right, but the technical specification is not? This is where we are in our element! Our interdisciplinary R&D team is at your service as a strong partner and solution finder. Contact us.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Request a personal consultation appointment now

Simply use our Contact Form to request a consultation appointment. Provide some information about your subject of interest, and we will get back to you as quickly as possible.

We look forward to your enquiry!