COMPLETENESS CHECK

Completeness check

EXAMPLE: FOOD INDUSTRY

Example: Food industry

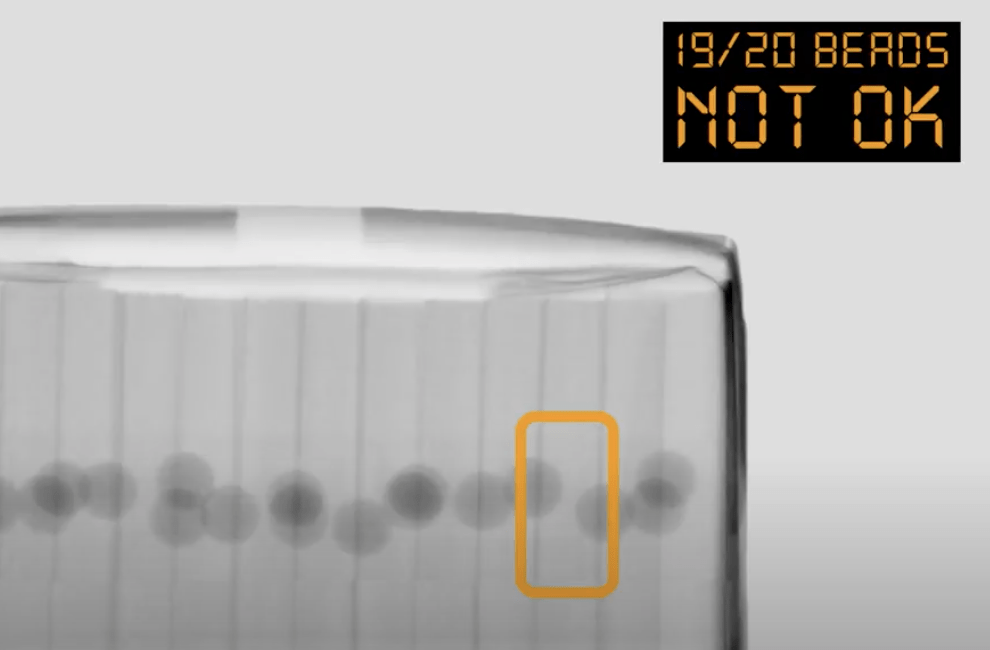

Regulations of retail chains, and of course the demands of end consumers, require that consumable products must always be offered for sale free of faults and complete in a closed package. A 100% inspection of all end products is necessary to guarantee a consistent consumer experience.

For these inspections, our systems can determine several things simultaneously, and they can do it real time. IMS systems give you the capability to always offer your customers faultless products. Typical application areas:

- Integrity check of the packaged products (e.g. no broken baked goods)

- Integrity check of the packaged products (e.g. no broken baked goods)

- Filling check (e.g. nuts in chocolate)

-

Check for completeness of packaging elements

(e.g. metal clips or included utensils)

EXAMPLE: INDUSTRY

Example: Industry

In the industrial sector, the focus is less on sales of pre-packaged products, and more on inspection of pre-assembled components; this is a frequently requested inspection task. Here, we can “see” into the housings of finished elements, and not only look for completeness of the components, we can also see (for example) how the individual cables are routed.

With the advance of 3D printing, even into the industrial sector, tasks in this area are becoming ever more frequent. With X-ray systems we can ensure that the structure of 3D printed components meets the specific requirements.

X-ray images, with their incredibly dynamic contrast range, offer advantages for many industrial products, in particular for the assembly or mounting of mixed materials of varying density (e.g. plastic/metal).

Typical applications

- Completeness check when casting a tool or potting electrical or electronic components

- Inspection of cable layout inside housing structures

- Integrity check of 3D print structures

- Inspection of weld seams or soldered joints

Request a personal consultation appointment now

Simply use our Contact Form to request a consultation appointment. Provide some information about your subject of interest, and we will get back to you as quickly as possible.

We look forward to your enquiry!