FOREIGN OBJECT DETECTION

Foreign object detection

EXAMPLE: FOOD INDUSTRY

Example: Food industry

Foreign objects can show up in food products and, to a certain extent, these may be natural characteristics of the product. Nut shells or pits, for example:

A cherry pit in a jar of jam is a classic that can almost be expected – not nice and not entirely without danger. However, a tiny rock that manages to make its way from the field into the muesli or even sharp-edged metal splinters, invisibly concealed in a frozen food product are direct health hazards. Hazards that every manufacturer of food products is well aware of.

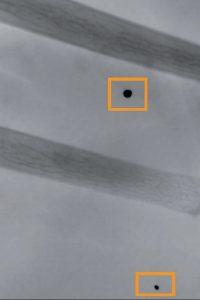

IMS X-ray inspection systems on the production line can prevent this risk early on, whatever the product consistency. They effectively detect foreign objects to less than 0.5 mm diameter. How the inspection is integrated into the production flows depends on the particular production situation.

The following items can be detected with particular reliability:

- Stones

- Metal particles

- Bone fragments

Depending on the product composition, the following foreign objects can also be detected:

- Hard plastic

- Glass

- Wood

EXAMPLE: INDUSTRY

Example: Industry

How can you avoid contamination of materials and products by foreign objects?

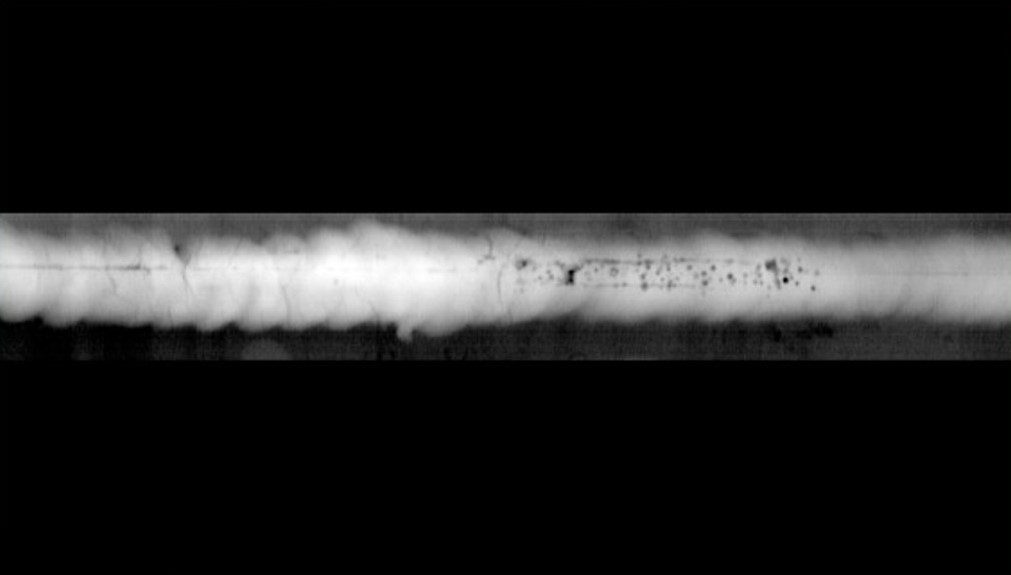

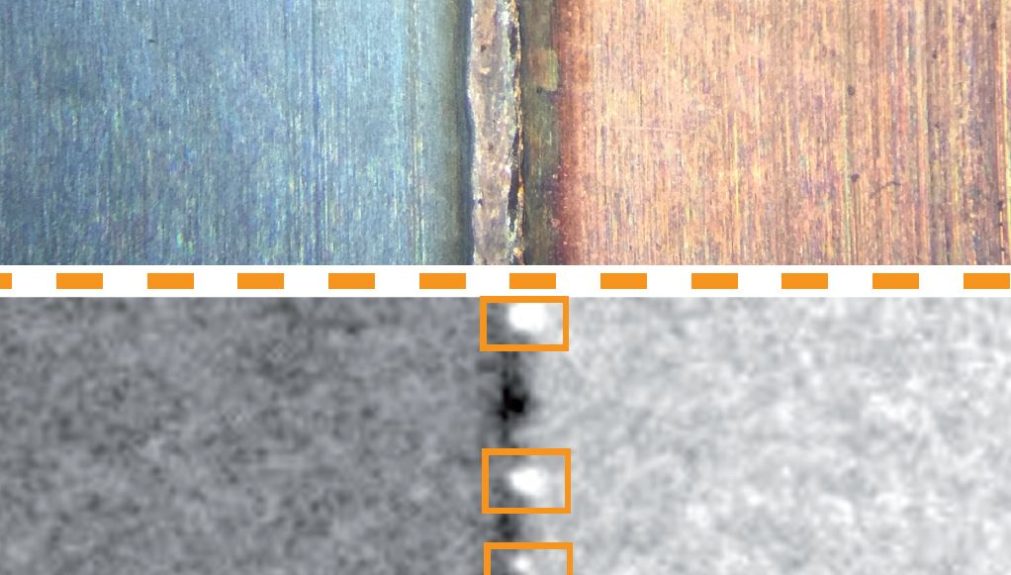

When manufacturing insulators or cabling, even the most minute contamination undetected during manufacture can later cause severe damage under full load. Whether air inclusions or metal abrasion from the CNC machine, the advanced and flexible image processing software from IMS can identify expected flaws based on rules, and it can also identify unforeseeable deviations from the target appearance.

The following occurrences can be detected:

- Inclusion of foreign material chips or splinters from other process steps

- Contamination through production resources which come into direct contact with the product

- Air inclusions in cast moulds

- Deviations in extrusion processes (e.g. tubes or hoses)

Request a personal consultation appointment now

Simply use our Contact Form to request a consultation appointment. Provide some information about your subject of interest, and we will get back to you as quickly as possible.

We look forward to your enquiry!