Efficient service

The requirements of our customers are the benchmark of our business activities. Only companies who can consistently deliver faultless products can compete long-term in the global market. Our safe, high-performance, and robust inspection systems and X-ray components ensure this. Used in running production processes and standalone systems, non-destructive material inspection is possible at all times. In recent years IMS Röntgensysteme GmbH has consistently grown by fulfilling these requirements.

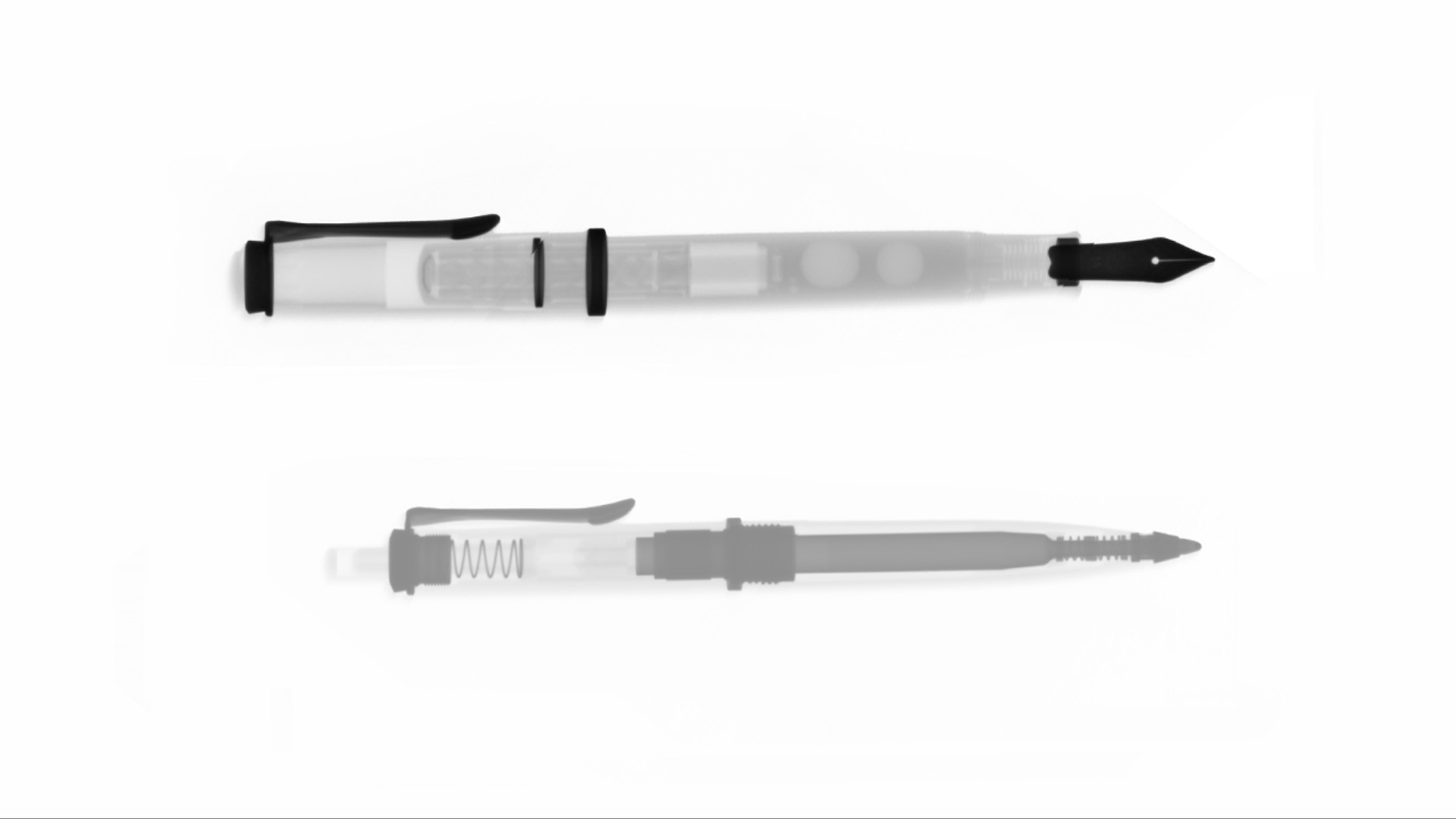

Since 2000, we have been developing and manufacturing X-ray generators, control systems, and complete systems, always to the clearly defined requirements of our customers. Our products include X-ray systems for measuring cold-rolled strip and hot-rolled strip thickness in steel manufacturing and for microstructure examination of fully assembled PCBs or the smallest castings. Our technology is also used in computer tomography and in the food industry, where it handles various detection, testing, inspection and measuring tasks.

Development support

X-ray radiation provides a valuable service in many areas, for example, in medical science, the security sector, non-destructive testing of components, and many other applications. In addition to these familiar solutions, new applications are identified almost daily.

X-ray technology is our core expertise. You are a leader in your field; do you want to further develop your products through use of inspection systems, and make them more efficient and sustainable? Your needs are our requirement specifications for the development of special solutions that open up competitive advantages to you beyond what is offered in any range of standard products.

Whether you need equipment for currently completely unknown applications, or are looking for alternatives for your existing system, together with you we develop and integrate the right solution. Please use the Enquiry Form below.

How can we accompany you in the development?

Explain to us very briefly what you are looking for. Together we will find the right solution.

Find the right system in three steps. An expert will contact you.

Feasibility study

Is X-ray technology familiar to you only through your medical applications? Are you looking for solutions for your production monitoring or quality checks, and conventional equipment is not up to the job or is too expensive? Have you already considered X-ray technology?

IMS has the know-how and the options for you to gain initial experience of the capacity of X-ray systems and of image processing on an industrial scale. Together we clarify and specify your needs, and then we test the feasibility of the identified solutions in our labs using our test equipment. But we are also at your service if you already have one of our systems and require support in refining the level of detail, or for determining optimal adjustment parameters.

Our qualified employees are available to you, and together we will determine the right solution. Please use the Enquiry Form below.

How can we accompany you in the development?

Explain to us very briefly what you are looking for. Together we will find the right solution.

Find the right system in three steps. An expert will contact you.

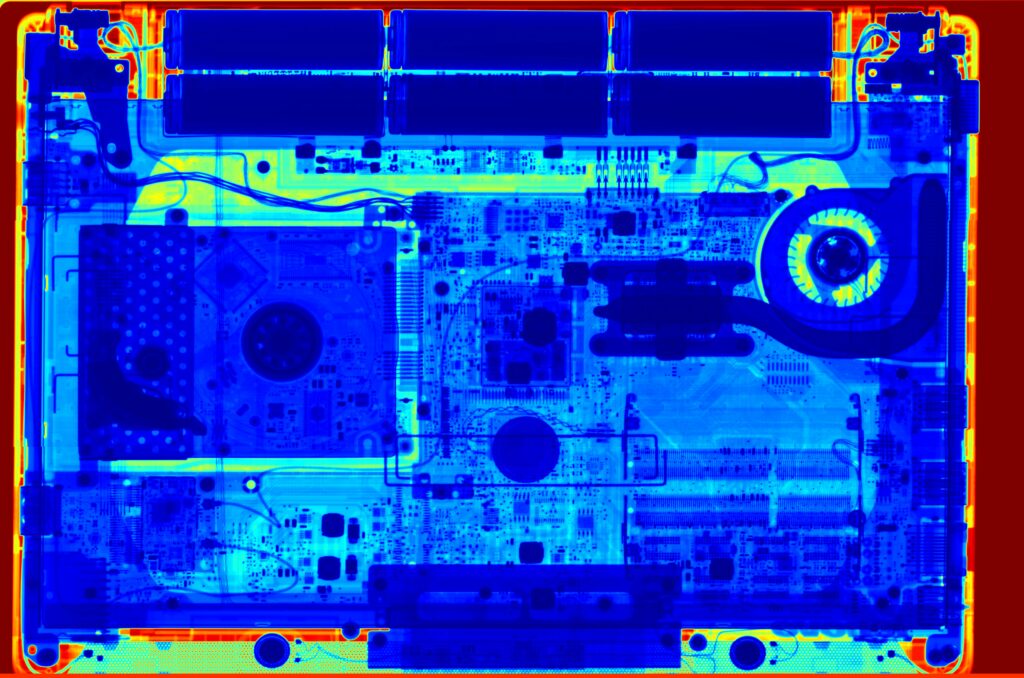

Calibration and laboratory services

In use, electro-technical products and electrical products are exposed to a wide variety of environmental influences, which they must withstand. Appropriate verification of environmental suitability and electromagnetic compatibility (EMC) must be provided before series launch. We support your development efforts with appropriate inspection and test methods in the form of preliminary assessments that simulate environmental impact in practical operation, but also during transport and storage. The combined tests in particular ensure an environmental impact that is corresponds to practical use. All tests are performed in strict compliance with standard DIN EN 17025. IMS Röntgensysteme GmbH has various facilities for in-house testing. The following tests can be performed – also in combination:

- Thermographic representation of temperature distribution

- Temperature tests, cold tests and hot tests

- Studies of cyclic ambient changes like resistance to temperture and moisture changes

- Testing the interference immunity to line-conducted disturbance variables, induced by HF fields, fast transient disturbances/burst, fast impulse voltages/surge, discharge of static electricity and much more.

- Selective immunity testing on PCBs

- X-ray tube test under different temperature conditions

- Real-time heating current measurement of X-ray generators under actual load conditions

- Dielectric strength test

The variety of possible tests requires the support of external testing laboratories. IMS Röntgensysteme GmbH works with various partners, and we would be pleased to discuss your requirements and advise you concerning the necessary tests; please us the Enquiry Form below.

How can we accompany you in the development?

Explain to us very briefly what you are looking for. Together we will find the right solution.

Find the right system in three steps. An expert will contact you.

Maintenance and repair

Even the best technologies and an extremely high-quality design require maintenance, recalibration, or possibly even repair from time to time. IMS designs all products as sustainable solutions, right from the start. IMS X-ray components therefore require only minimal care and cleaning. To ensure the value and availability of your IMS device, we recommend regular inspection and maintenance. During each maintenance routine the following points are checked and executed:

Owners or operators of components or systems delivered by IMS receive a handbook with guidelines for availability and value retention. IMS Röntgensysteme GmbH also has additional service and support offerings. We would be pleased to advise you. Please use the Enquiry Form below.

How can we accompany you in the development?

Explain to us very briefly what you are looking for. Together we will find the right solution.

Find the right system in three steps. An expert will contact you.